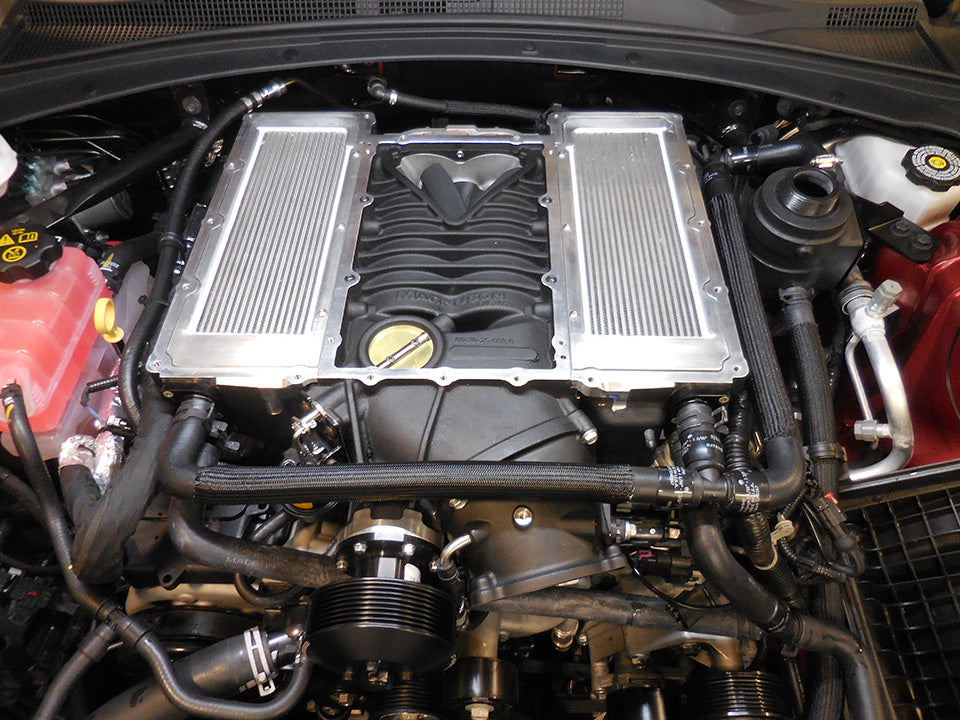

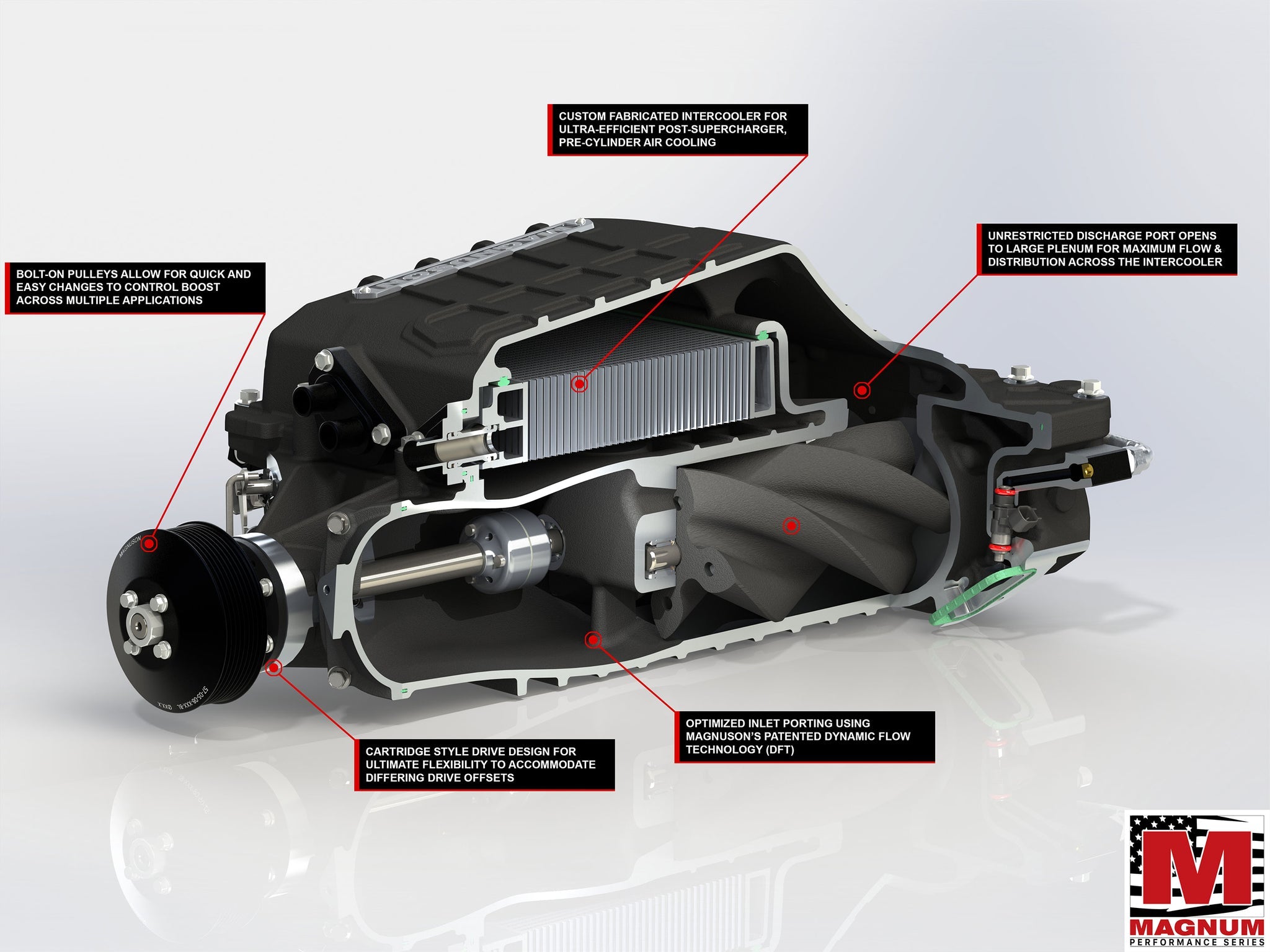

Take the guesswork out of designing your Supercharger Cooling system with the Magnuson Universal Supercharger Cooling System. Expertly crafted using top-of-the-line components that are identical to those found in our application-specific supercharger systems, this cooling system is the perfect addition to help take your build to the next level.

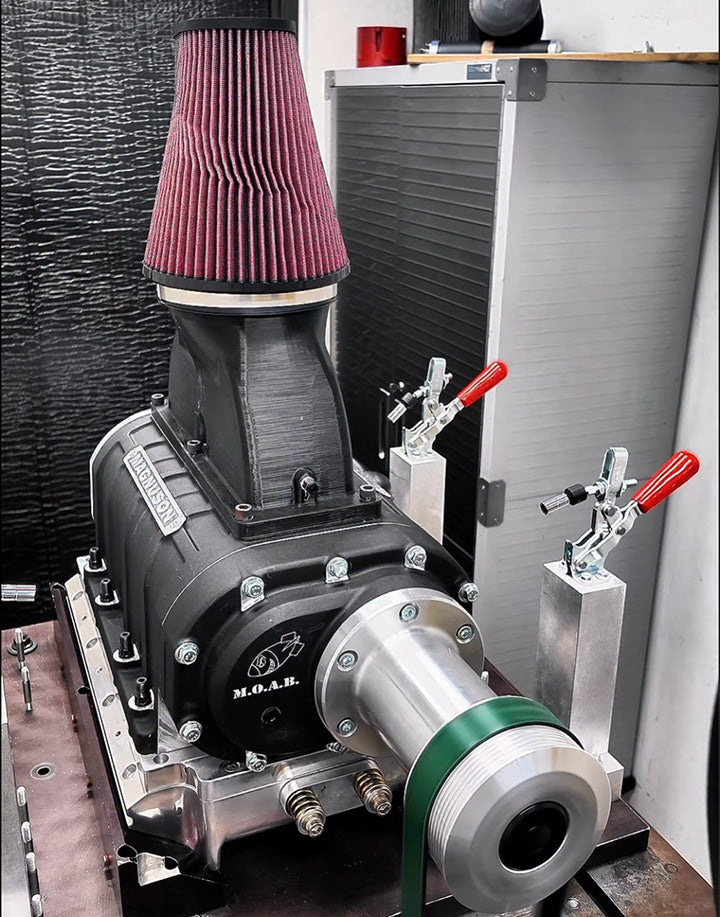

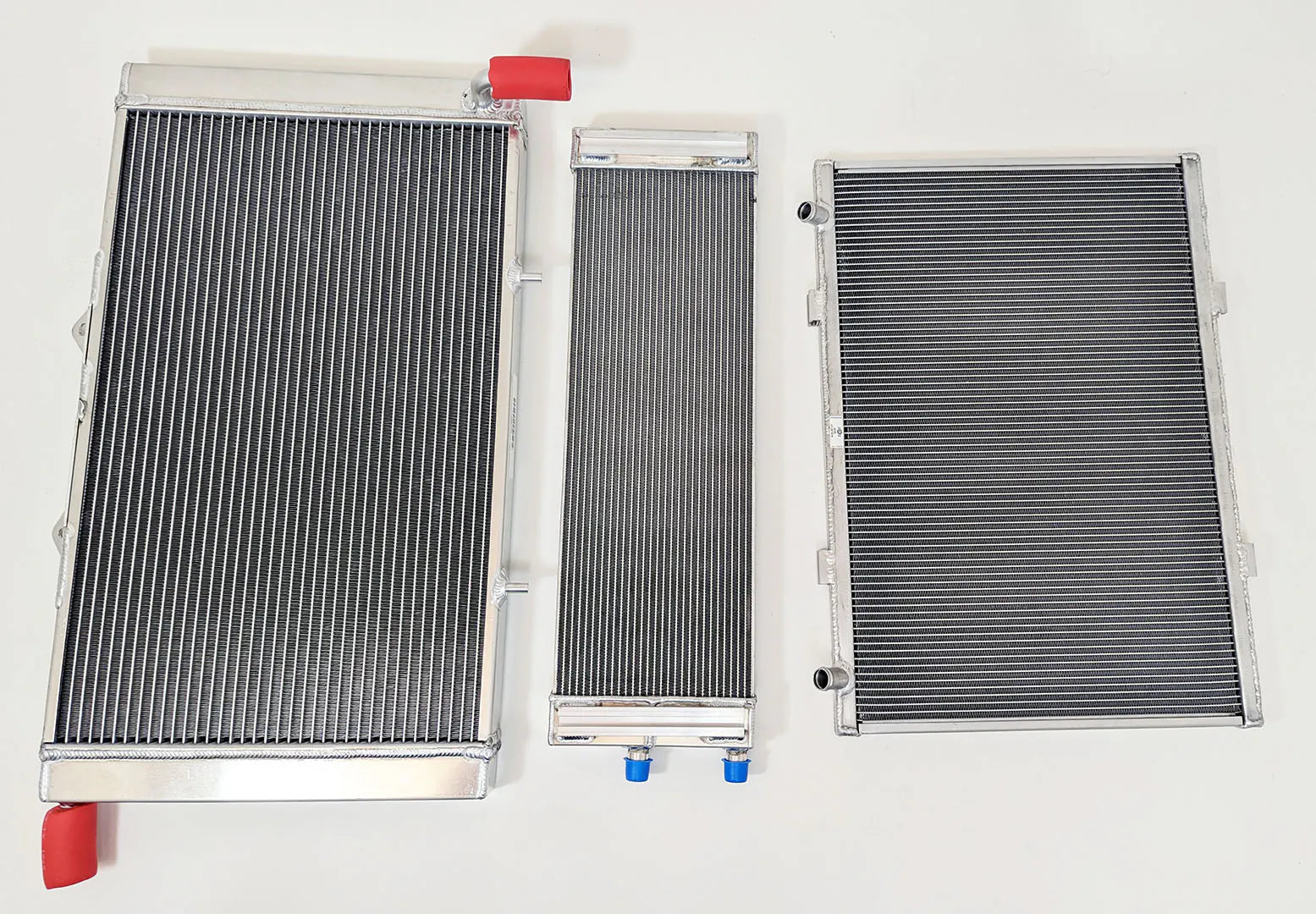

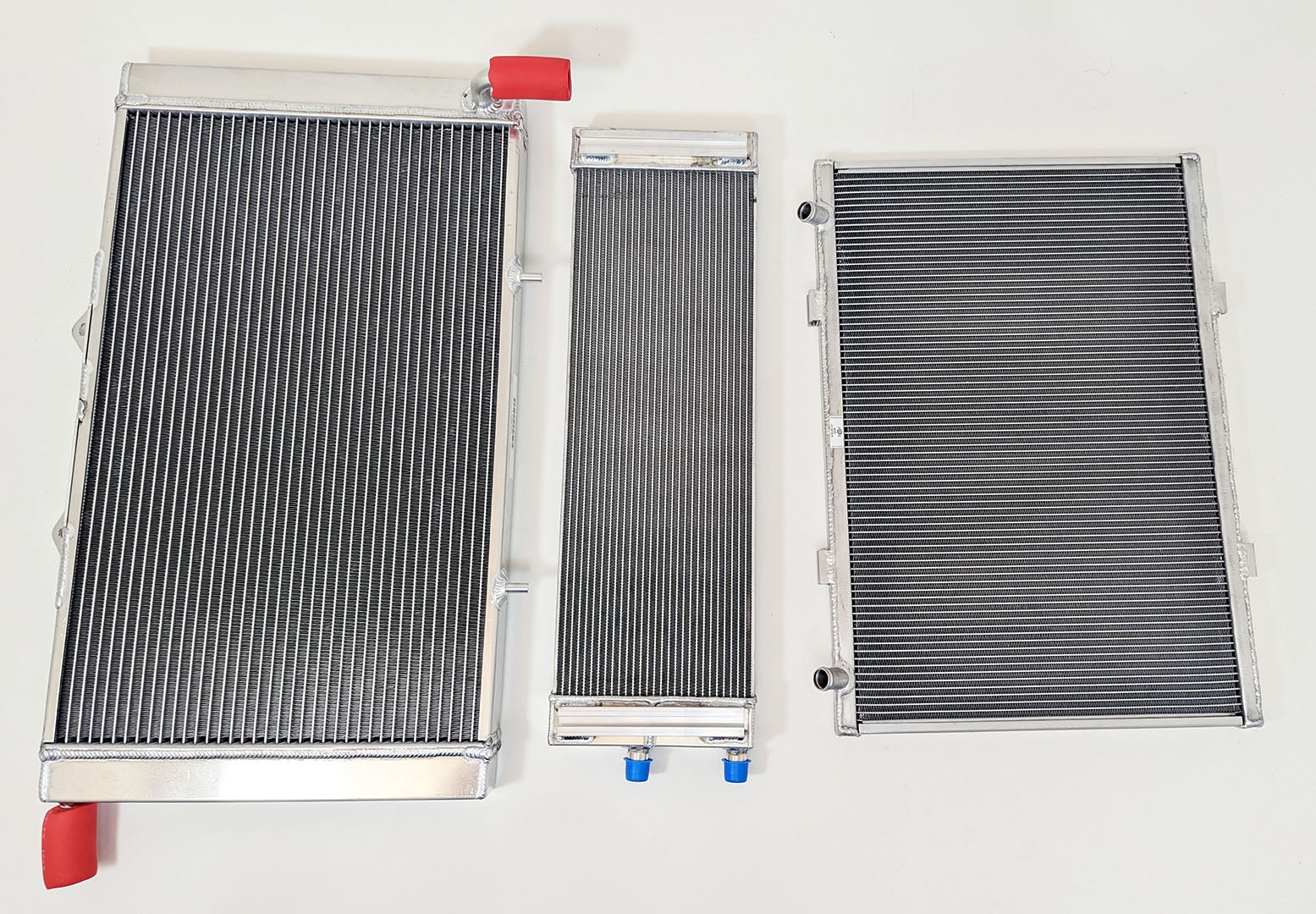

These universal cooling systems are the perfect addition to any of the Magnuson Hot Rod head unit offerings. Designed to provide you with most of the necessary components to cool your supercharger in engine swap applications, the Magnuson Universal Supercharger Cooling System comes in three sizes of highly efficient aluminum Low Temperature Radiators (LTR). These LTRs are built to fit into a wide range of vehicles, ensuring that your supercharger has maximum cooling efficiency.

So why wait? Cut out the guesswork and buy a Magnuson Universal Supercharger Cooling System today.

*Universal Cooling Systems ship with an estimated lead-time of 4 weeks.